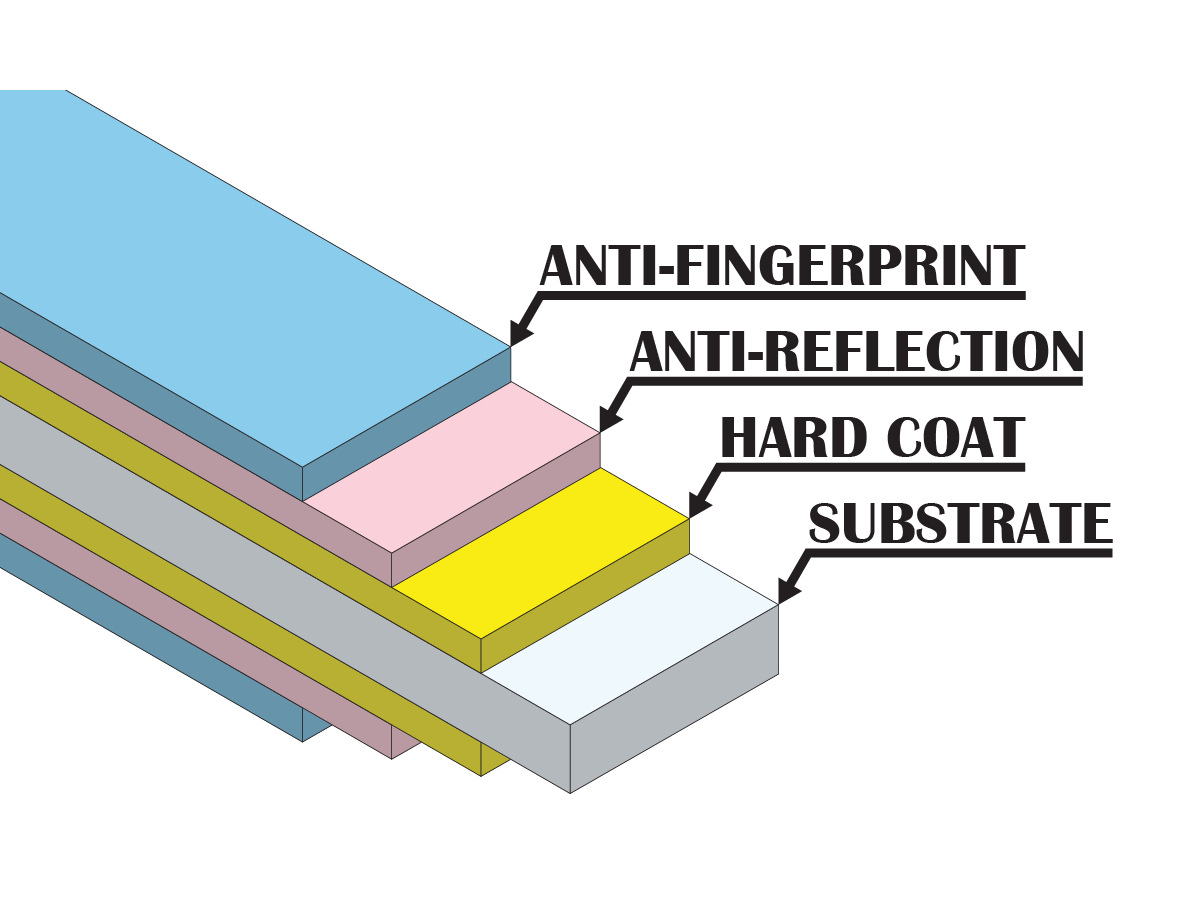

IML-AR Structure

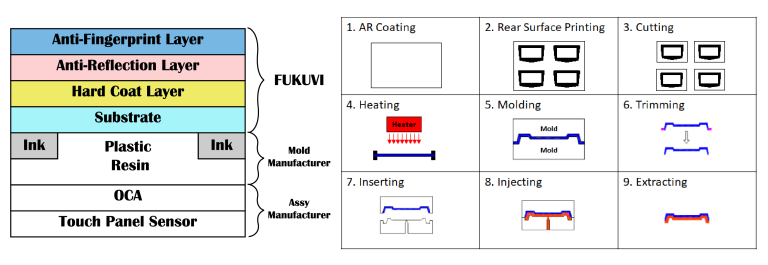

Harzlas IML-AR is a series of thin-film layers coated on plastic substrates. Typically, it consists of a hard coat layer, AR layers, and an anti-fingerprint layer. The flexible AR coating can withstand most thermoforming processes allowing for use in insert molding. We can customize the layers to meet the requirements for your project.

- Developed specially for products with 3D surfaces made by insert molding

- The anti-reflective coating is applied to a sheet before the insert molding process, leading to edge-to-edge coating uniformity

Properties

Low Reflectance

Reduce the amount of light that gets reflected to the user.

High Transmittance

Improved clarity allows you to see the other side without hindrance.

High Chemical Resistance

Cleanable with common household chemicals without worrying about deteriorating the coating.

Water and Oil Repellent

Easy clean smudges and fingerprints with our specially formulated anti-fingerprint coating.

High Durability

Excellent scratch and abrasion resistance for long lasting usability.

Consistent Reflected Color

Our highly controlled production process allows for the coating to be evenly applied at the nanometer level, resulting in a consistent reflection color throughout the substrate.

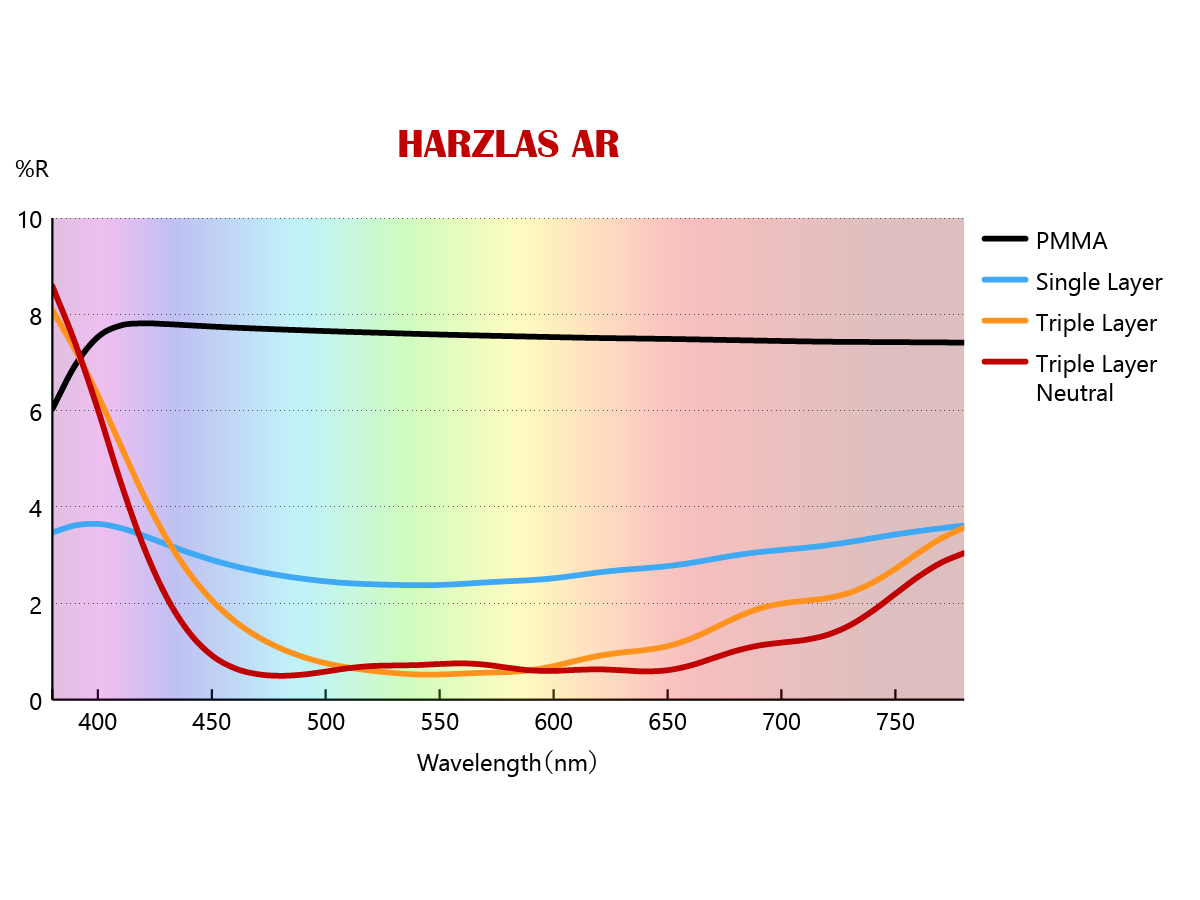

Optical Properties

Reflectance

Harzlas AR can be optimized from three basic starting points.

- For projects that need extremely low reflectance, our triple-layer solutions are optimal.

- If reflected color is an issue, Harzlas AR is available in a more neutral reflected color.

- For projects that allow for more reflectance, our single-layer option is an optimal starting point.

Transmittance

Environmental Resistance Tests

| Test | Conditions | Result |

|---|---|---|

| High Temperature | 100C for 192 hours | No Deterioration in Optical Properties or Adhesion |

| Low Temperature | -40C for 192 hours | No Deterioration in Optical Properties or Adhesion |

| Thermal Shock | -40C to 95C, 200 cycles, 30 minutes per temperature | No Deterioration in Optical Properties or Adhesion |

| High Heat and Humidity | 65C, 95%RH, 192 hours | No Deterioration in Optical Properties or Adhesion |

Chemical Resistance Tests

| Test | Conditions | Result |

|---|---|---|

| Tap Water | 25C, 96 hours | No Deterioration in Adhesion |

| 5% Saline Solution | 25C, 96 hours | No Deterioration in Adhesion |

| Acidic Artificial Sweat | 25C, 96 hours | No Deterioration in Adhesion |

| Alkaline Artificial Sweat | 25C, 96 hours | No Deterioration in Adhesion |

Let us work together to find a coating optimized for your application.