The Harzlas AR Production Process

Anti-reflective sheets are made by adding a thin layer of material to a substrate to purposefully cause the destructive interference of reflected light. Harzlas is based on organic thin-film technology and is made through a process called “the wet coating method.” Fukuvi’s coating technology uses the dipping method. This wet coating method differs from more conventional inorganic “dry coating” anti-reflection application methods such as vacuum deposition.

Conventional AR

Conventional AR sheets are made by vacuum deposition.

In this method, the substrate is placed in a vacuum chamber together with an AR particle source. The AR source is heated to make the material evaporate or sublimate, causing particles to form a thin layer of the material on the substrate.

HARZLAS AR

Harzlas AR sheets are made by wet coating.

Fukuvi's wet coating technology dips sheets into tanks filled with our original coating solution. By lifting them out of these tanks, the surface is coated with a thin-film intereference layer.

Advantages of Harzlas AR

- With conventional AR, each sheet has to be coated one side at a time. Harzlas coats both sides at the same time.

- Harzlas can be applied to a variety of substrates including acrylic, polycarbonate, polycarbonate/acrylic composite sheets, and glass.

- Harzlas has excellent solvent resistance to everyday substances such as tap water, salt spray, and sweat.

- While conventional AR uses inorganic compounds to survive the conditions in the vacuum chamber, Harzlas is organic based, making it more resistant to cracking and sudden temperature fluctuations.

- The Harzlas coating process is carefully controlled at the nano scale producing a uniform layer thickness that leads to a consistent color being reflected throughout the sheet.

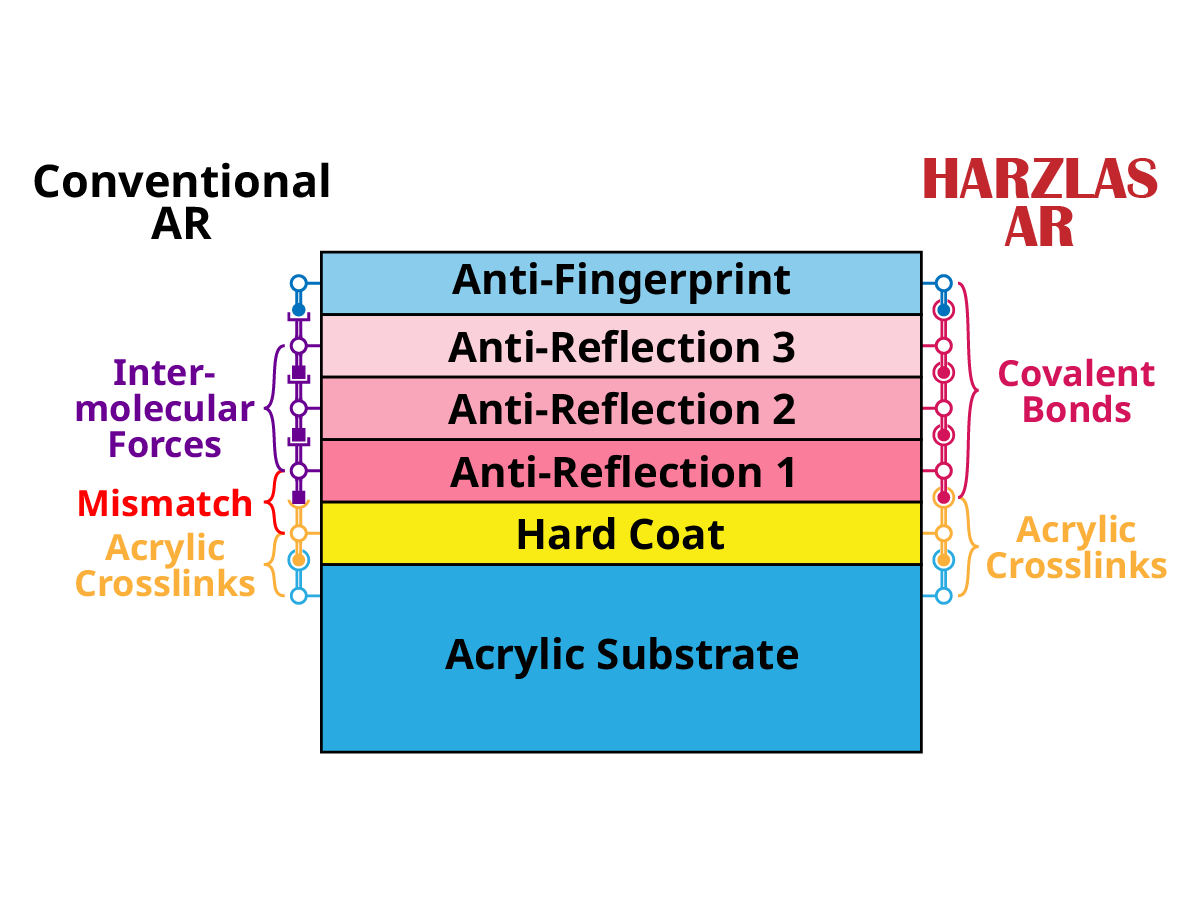

- Since all of the Harzlas materials from substrate to coating solution are made of organic compounds, strong covalent bonds keep the layers bonded together as one for a scratch resistant, durable product.

Do you need help coating your product with AR?

Wet coatings allows for a wide variety of materials to be used, opening a whole wide world of possibilities. Harzlas technology can create anti-reflective coatins, half-mirror coatings, super hard coats, and more. We can help you find a Harzlas product that matches your needs.