ARG Structure

Building on our expertise in coating plastic substrates, Harzlas ARG is a series of thin-film layers coated on glass substrates with superb coating adhesion. ARG consists of AR layers with an additional anti-fingerprint layer to improve ease of cleaning. We can customize the layers to meet the requirements for your project.

Properties

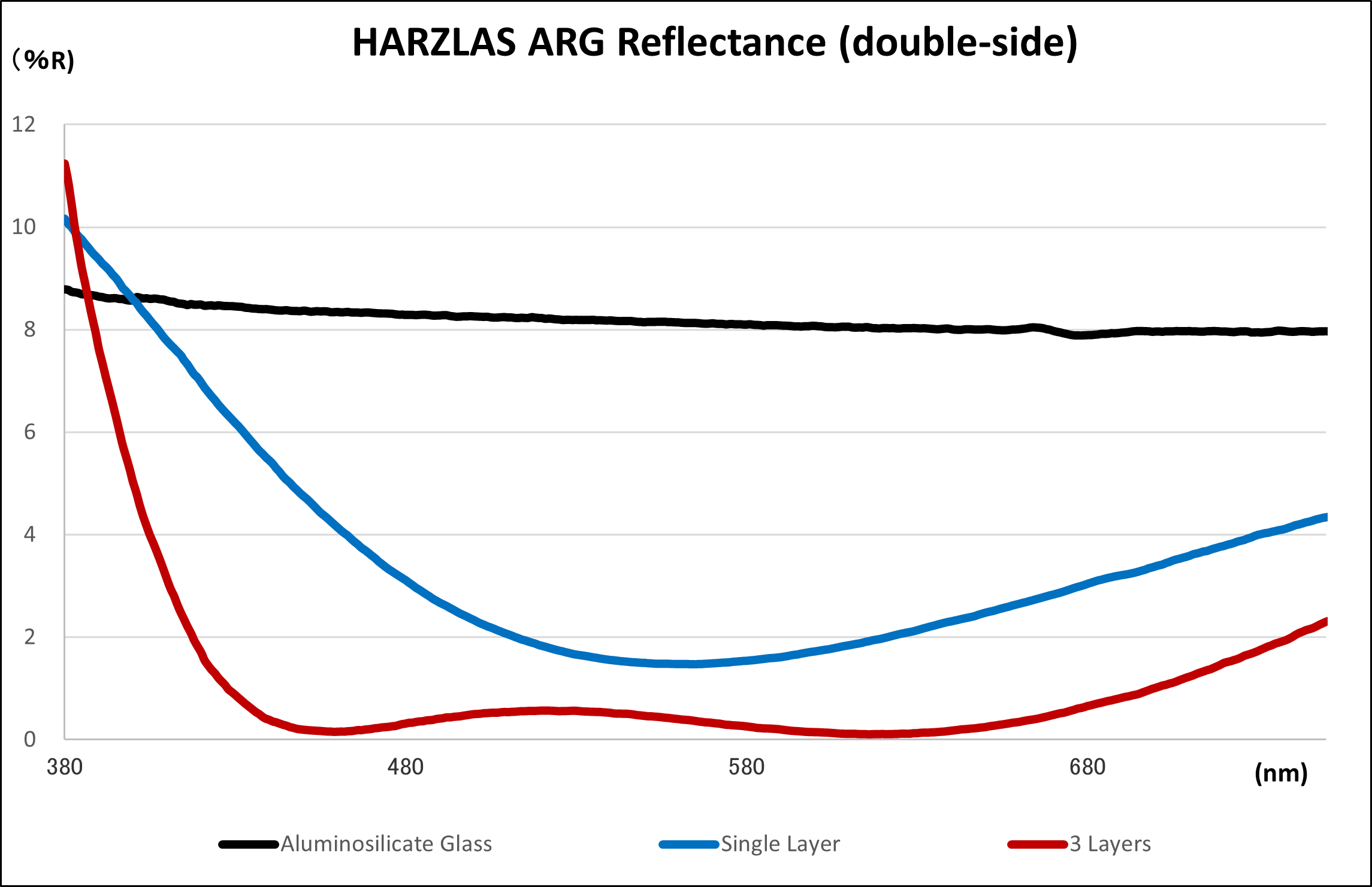

Low Reflectance

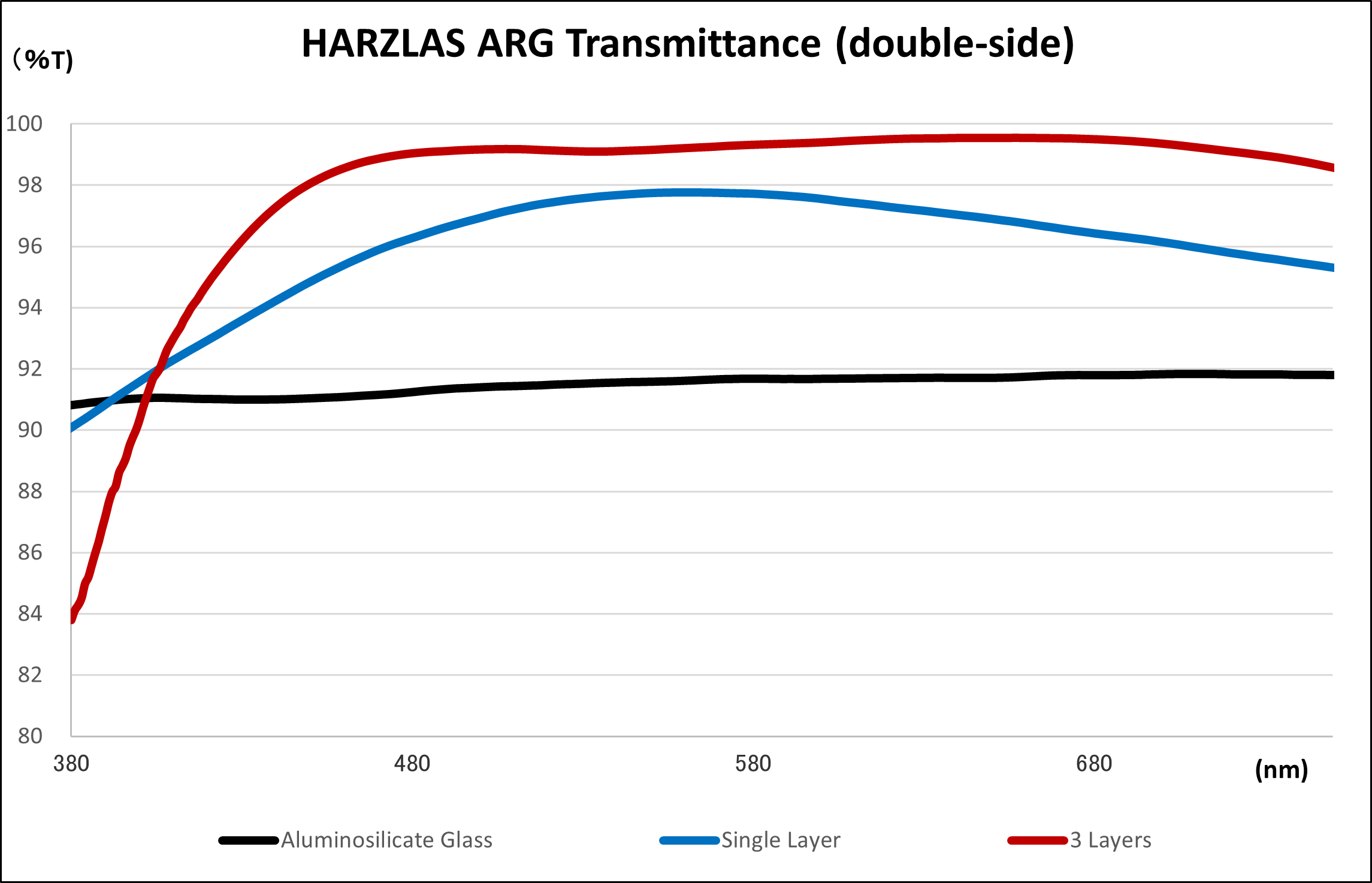

High Transmittance

Improved clarity allows you to see the other side without hindrance.

High Chemical Resistance

Cleanable with common household chemicals without worrying about deteriorating the coating.

Water and Oil Repellent

Easy clean smudges and fingerprints with our specially formulated anti-fingerprint coating.

High Durability

Excellent scratch and abrasion resistance for long lasting usability.

Consistent Reflected Color

Our highly controlled production process allows for the coating to be evenly applied at the nanometer level, resulting in a consistent reflection color throughout the substrate.

Processing After AR Coating

Processing Advantages of ARG

Conventional AR Glass Processing

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|

|

Untreated Glass |

Cut | Heat Bending | Chemical Strenghtening |

AR Application 1 or 2 Sides |

Anti-Fingerprint | Printing | ITO/FPC | |

|

|

|

|

|||||

HARZLAS ARG Processing

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|

|

Untreated Glass |

AR Application 1 or 2 Sides |

Cut | Heat Bending | Chemical Strenghtening | Anti-Fingerprint | Printing | ITO/FPC |

|

|

|

|

||||

Properties

Flexible Coating

Compatible with design containing smaller radii of curvature. For example, Harzlas ARG can achieve a minimum R of 25 mm on 1.1 mm thick glass.

Consistent Color

Harzlas ARG's coating thickness is controlled at the nanometer level for a consistent reflected color throughout the sheet.

Superb Adhesion

Coating on 1 or 2 Sides

Harzlas ARG is applied before any traditional glass processing is performed. The coating is able to withstand typical glass processing procedures.

Optical Properties

Reflectance

Transmittance

Note: The above data are based on 1.1 mm thick aluminosilicate glass that has the AR treatment on both sides. Single-sided AR and coating on soda-lime glass is also available. Alternate solutions beyond those listed here may be available. Please contact us for more information.

Environmental Resistance Tests

| Test | Conditions | Result |

|---|---|---|

| High Temperature | 100C for 192 hours | No Deterioration in Optical Properties or Adhesion |

| Low Temperature | -40C for 192 hours | No Deterioration in Optical Properties or Adhesion |

| Thermal Shock | -40C to 95C, 200 cycles, 30 minutes per temperature | No Deterioration in Optical Properties or Adhesion |

| High Heat and Humidity | 65C, 95%RH, 192 hours | No Deterioration in Optical Properties or Adhesion |

Chemical Resistance Tests

| Test | Conditions | Result |

|---|---|---|

| Tap Water | 25C, 96 hours | No Deterioration in Adhesion |

| 5% Saline Solution | 25C, 96 hours | No Deterioration in Adhesion |

| Acidic Artificial Sweat | 25C, 96 hours | No Deterioration in Adhesion |

| Alkaline Artificial Sweat | 25C, 96 hours | No Deterioration in Adhesion |

Weatherability Testing

Note: Tested on a Sunshine Weather Meter with light irradiance and water spray at 63C for 500 hours. Harzlas ARG can be used for outdoor applications, as it maintains its anti-fingerprint and AR properties. preventing water spots from remaining on the surface.